3D printing technology is revolutionizing industries, from healthcare to architecture, fashion, and even the food industry. This innovative technology is transforming the way we create, design, and produce an endless array of products and items. The impact of 3D printing technology is far-reaching, and its potential is only just starting to be realized. This post will explore the incredible impact of 3D printing technology, including how it’s being used in different industries, how it’s changing the manufacturing process, and what the future holds for this innovative technology. Join us as we delve into the incredible world of 3D printing and discover how it’s shaping the future of industries around the world.

1. INTRODUCTION TO 3D PRINTING TECHNOLOGY AND ITS REVOLUTIONARY POTENTIAL

In the vast realm of technological advancements, one innovation has been turning heads and capturing imaginations with its transformative capabilities – 3D printing technology. This groundbreaking technology has revolutionized industries across the globe, opening up a world of endless possibilities.

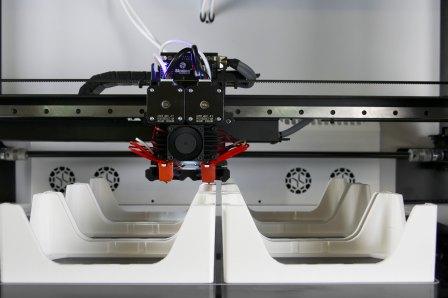

At its core, 3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials on top of each other, following a digital design. Unlike traditional manufacturing methods that involve cutting and shaping materials, 3D printing builds objects layer by layer, resulting in intricate and highly customizable creations.

The impact of 3D printing technology is far-reaching, disrupting various sectors such as healthcare, aerospace, automotive, fashion, and even the culinary world. With its ability to produce complex and precise designs, 3D printing has transformed the manufacturing landscape, offering unparalleled efficiency, cost-effectiveness, and design flexibility.

One of the most significant advantages of 3D printing is its ability to create custom-made products tailored to individual needs and preferences. This level of personalization has revolutionized industries like healthcare, where prosthetics, dental implants, and even organs can be crafted specifically for each patient. This not only enhances the quality of life for individuals but also reduces costs and waiting times associated with traditional manufacturing processes.

Moreover, the aerospace industry has embraced 3D printing technology to streamline production, reduce weight, and improve fuel efficiency. Complex engine parts, lightweight aircraft components, and even entire rockets have been successfully printed, pushing the boundaries of what was once considered possible.

In the fashion industry, designers have embraced 3D printing to create avant-garde garments, intricate accessories, and footwear that push the boundaries of traditional design. This technology allows for the creation of unique and intricate designs that were once deemed unattainable, providing endless creative possibilities.

The culinary world has also witnessed the transformative power of 3D printing, with chefs experimenting with the creation of edible masterpieces. Intricate chocolate sculptures, customized cake toppers, and even intricate sugar art can now be crafted with precision, adding a new dimension to culinary creativity.

As 3D printing continues to evolve and become more accessible, its impact on various industries will only continue to grow. The ability to create complex, customizable, and cost-effective products has opened up new avenues for innovation, creativity, and problem-solving.

In this blog series, we will delve deeper into the realm of 3D printing technology, exploring its applications in different industries, the challenges it faces, and the future potential it holds. Join us on this exciting journey as we uncover the revolutionary impact of 3D printing and its transformative power across industries.

2. A BRIEF HISTORY OF 3D PRINTING AND ITS EVOLUTION

A brief history of 3D printing and its evolution is crucial to understanding the impact this groundbreaking technology has had on various industries. The concept of 3D printing, also known as additive manufacturing, originated in the 1980s, but its roots can be traced back to the 1970s when the first working 3D printer was created by David E. H. Jones.

However, it wasn’t until the early 2000s that 3D printing started to gain significant attention and advancement. The expiration of key patents allowed for greater innovation and accessibility, leading to the democratization of this technology. As a result, 3D printers became more affordable and accessible to individuals, small businesses, and industries alike.

The 3D printing evolution technology has a remarkable short of thing in this technological world. In the early stages, 3D printers primarily utilized plastic materials, such as ABS and PLA, to create simple prototypes and models. However, as technology progressed, the range of materials expanded to include metals, ceramics, and even biological substances.

Moreover, the capabilities of 3D printers have advanced significantly, allowing for the creation of complex and intricate designs with high precision and accuracy. From aerospace and automotive industries to healthcare and fashion, 3D printing has revolutionized the way products are designed, prototyped, and manufactured.

One of the key advancements in 3D printing technology is the development of advanced software and modeling techniques. This has enabled designers and engineers to bring their ideas to life in a virtual environment, optimizing designs before printing them physically. The use of computer-aided design (CAD) software and 3D modeling has played a crucial role in pushing the boundaries of what is possible with 3D printing.

In recent years, the field of 3D printing has witnessed remarkable breakthroughs. From printing human organs for transplantation to constructing buildings using large-scale 3D printers, the potential applications of this technology seem boundless. As research and development continue to push the boundaries, 3D printing is set to reshape industries and redefine the way we think about manufacturing and production.

In the next section, we will delve deeper into the specific industries that have been revolutionized by 3D printing, exploring the transformative impact it has had on sectors such as healthcare, automotive, aerospace, and more.

3. INDUSTRIES THAT HAVE BEEN TRANSFORMED BY 3D PRINTING TECHNOLOGY

3D printing technology has revolutionized numerous industries, pushing the boundaries of what was once thought possible. From healthcare to manufacturing, the impact of this innovative technology is undeniable.

In the healthcare sector, 3D printing has opened up a world of possibilities. It helps to enable the creation of personalized implants, human organs and sometimes prosthetics. With the ability to print complex and customized medical devices, patients can now receive treatments that are tailor-made for their specific needs. This has not only improved patient outcomes but has also reduced costs and waiting times.

The manufacturing industry has also undergone a significant transformation with the advent of 3D printing. Traditional manufacturing processes often involve complex tooling and assembly lines, which can be time-consuming and expensive. However, with 3D printing, objects can be printed layer by layer, bypassing the need for many of these traditional methods. This has resulted in faster production times, reduced waste, and increased design flexibility. Companies can now create prototypes and iterate designs more rapidly, leading to improved product development cycles.

Architecture and construction have also seen a remarkable impact from 3D printing technology. The ability to print large-scale structures and intricate architectural models has transformed the way buildings are designed and constructed. With the use of specialized 3D printers and durable materials, architects can now turn their visions into reality with greater precision and efficiency. This not only saves time and labor costs but also allows for more sustainable building practices.

Even the fashion industry has been influenced by 3D printing. Designers can now create elaborate and intricate garments that were previously impossible to achieve with traditional manufacturing methods. 3D printed fashion pieces have graced runways, showcasing the endless possibilities that this technology offers in terms of design, customization, and sustainability.

These are just a few examples of the many industries that have been transformed by 3D printing technology. As this technology continues to evolve and become more accessible, we can expect even greater advancements and innovations in various fields. The impact of 3D printing is far-reaching, revolutionizing the way we create, manufacture, and ultimately, live.

4. ADVANTAGES AND BENEFITS OF USING 3D PRINTING IN VARIOUS INDUSTRIES

The impact of 3D printing technology on various industries cannot be overstated. This revolutionary technology has opened up a world of possibilities, offering numerous advantages and benefits that are transforming the way businesses operate. Let’s delve into some of the key advantages of using 3D printing in different industries.

One of the primary benefits of 3D printing is its ability to streamline and accelerate the manufacturing process. Traditional manufacturing methods often involve complex and time-consuming processes, such as mold creation and assembly. With 3D printing, objects can be created directly from a digital design, eliminating the need for molds and reducing production time significantly. This not only allows for faster product development and delivery but also enables businesses to respond quickly to changing market demands.

Another advantage of 3D printing is its cost-effectiveness. Traditional manufacturing often involves high setup costs, especially for small-scale production runs or prototypes. On the other hand, 3D printing enables on-demand production, eliminating the need for large inventories and reducing storage costs. Additionally, the ability to create complex geometries and designs with 3D printing eliminates the need for multiple parts and assembly, further reducing material and labor costs.

In terms of customization, 3D printing offers unparalleled freedom. This technology allows for the creation of highly personalized and tailored products, catering to individual customer preferences. Whether it’s customized medical implants, personalized fashion accessories, or unique architectural designs, 3D printing enables businesses to meet the specific needs and desires of their customers, enhancing customer satisfaction and loyalty.

Furthermore, 3D printing promotes sustainability and environmental consciousness. Traditional manufacturing methods often result in significant material wastage, as excess materials are discarded after production. With 3D printing, materials are used more efficiently, as only the necessary amount is utilized for each printed object. Additionally, 3D printing enables the use of recycled materials, further reducing environmental impact and promoting a circular economy.

Lastly, 3D printing fosters innovation and experimentation. Its versatility allows for rapid iteration and prototyping, empowering businesses to test new ideas and designs without incurring significant costs. This promotes a culture of innovation, enabling businesses to stay ahead of the competition and continually improve their products and processes.

In conclusion, the advantages and benefits of using 3D printing in various industries are vast and transformative. From faster and cost-effective production to customization, sustainability, and innovation, 3D printing is revolutionizing industries and paving the way for a future where creativity and efficiency go hand in hand.

5. CASE STUDIES SHOWCASING THE IMPACT OF 3D PRINTING IN SPECIFIC SECTORS

As 3D printing technology continues to advance, its impact on various industries becomes increasingly evident. In this section, we will explore some compelling case studies that highlight the transformative power of 3D printing in specific sectors.

- Healthcare: In the field of healthcare, 3D printing has revolutionized patient care. It allows for the creation of customized prosthetics, implants, and medical models that perfectly fit individual patients’ needs. Surgeons can now practice complex procedures on accurate 3D-printed models, reducing surgical risks and improving patient outcomes. Additionally, 3D bioprinting holds the potential to revolutionize organ transplantation, as researchers continue to make progress in printing functional human tissues and organs.

- Automotive: The automotive industry has embraced 3D printing for its ability to rapidly produce prototypes and parts. With 3D printing, manufacturers can create complex and lightweight components that were previously challenging or impossible to produce using traditional manufacturing methods. This technology enables faster product development cycles, cost savings, and customization options for car manufacturers.

- Aerospace: 3D printing has made significant contributions to the aerospace industry. By utilizing lightweight materials and intricate designs, aerospace engineers can create complex components that are both durable and lightweight. This reduces the weight of aircraft, leading to improved fuel efficiency and reduced emissions. Moreover, 3D printing allows for on-demand production and customization, reducing the need for large inventories or waiting times for spare parts.

- Fashion and Design: 3D printing has opened up new possibilities in the world of fashion and design. Designers can now create intricate and avant-garde pieces that were previously unattainable. Customization and personalization are also key benefits, as consumers can have clothing and accessories tailored specifically to their measurements and preferences. This technology is pushing the boundaries of creativity and transforming the way fashion items are produced and consumed.

These case studies represent just a glimpse into the vast potential of 3D printing technology across industries. As this technology continues to evolve, we can expect further advancements, opening up new opportunities for innovation and disruption. The future of manufacturing and production is undoubtedly being reshaped by the transformative power of 3D printing.

6. CHALLENGES AND LIMITATIONS OF 3D PRINTING TECHNOLOGY

While 3D printing technology has been hailed as a game-changer in various industries, it is not without its challenges and limitations. As with any emerging technology, there are hurdles to overcome and areas where improvements can be made.

One of the primary challenges of 3D printing technology lies in its speed and scalability. While the technology has advanced significantly over the years, the process of creating complex and intricate objects can still be time-consuming. Large-scale production using 3D printing can be limited due to the slower printing speeds compared to traditional manufacturing methods. However, ongoing research and development efforts are focused on addressing these challenges to enhance the speed and efficiency of the 3D printing process.

Another limitation of 3D printing technology is the range of materials available for printing. Although there is a wide variety of materials that can be used in 3D printers, the options are not as extensive as those available in traditional manufacturing. This can restrict the scope of applications and industries that can fully leverage the benefits of 3D printing. However, researchers and material scientists are constantly exploring new materials and improving existing ones to expand the possibilities of 3D printing.

Cost is another factor that poses challenges for widespread adoption of 3D printing technology. While the cost of 3D printers has significantly decreased in recent years, the cost of materials and maintenance can still be relatively high. Additionally, the expertise required to operate and maintain 3D printers can be a barrier for some businesses. However, as the technology continues to evolve and become more accessible, these cost-related challenges are expected to diminish over time.

Furthermore, intellectual property and copyright concerns arise with the increasing accessibility of 3D printers. The ease of replicating objects using 3D printing technology raises questions about the protection of designs and ownership rights. Striking a balance between promoting innovation and protecting intellectual property will be an ongoing challenge for industries as 3D printing technology becomes more prevalent.

Despite these challenges and limitations, the potential of 3D printing technology to revolutionize industries is undeniable. With ongoing advancements and breakthroughs, the limitations of speed, material options, cost, and intellectual property are expected to be addressed, paving the way for a future where 3D printing plays a significant role in transforming manufacturing processes and product development.

7. FUTURE TRENDS AND ADVANCEMENTS IN 3D PRINTING

The world of 3D printing is rapidly evolving, and the future holds exciting possibilities for this groundbreaking technology. As researchers and innovators continue to push the boundaries of what is possible, we can expect to witness remarkable advancements that will revolutionize various industries.

One of the most significant future trends in 3D printing is the development of new materials. While current 3D printers primarily use plastics and metals, scientists are actively exploring the use of advanced materials such as ceramics, biomaterials, and even food-grade substances. This opens up a world of possibilities for creating complex and functional objects with unique properties.

Another exciting advancement on the horizon is the ability to print larger and more intricate structures. Currently, most 3D printers have size limitations due to the constraints of the printing process. However, ongoing research aims to overcome these limitations by developing new printing techniques and equipment. This could pave the way for printing entire buildings, large-scale industrial components, and even organs for transplantation.

Furthermore, the integration of 3D printing with other cutting-edge technologies promises to reshape industries. For instance, combining 3D printing with artificial intelligence and robotics can enable autonomous manufacturing processes, where machines can self-optimize and adapt to produce highly customized products efficiently. This integration can lead to significant advancements in industries such as healthcare, aerospace, and automotive manufacturing.

Additionally, the concept of 4D printing is gaining attention as a future trend in this field. 4D printing involves the creation of objects that can change their shape or behavior over time. By using smart materials that respond to external stimuli, such as temperature or humidity, 4D printed objects can self-assemble or transform into different forms. This technology has great potential in various applications, such as adaptive architecture, self-repairing structures, and responsive medical devices.

As 3D printing continues to innovate and disrupt industries, it is crucial for businesses and professionals to stay updated with these future trends. Embracing and leveraging the advancements in 3D printing technology can provide companies with a competitive edge, allowing them to create innovative products, streamline manufacturing processes, and meet the ever-growing demands of consumers.

In conclusion, the future of 3D printing holds immense potential for transforming industries as new materials, larger structures, integration with advanced technologies, and the concept of 4D printing continue to evolve. By staying informed about these future trends and embracing the possibilities they offer, businesses can position themselves at the forefront of this revolution, driving innovation and redefining the way we manufacture and create.

8. POTENTIAL IMPLICATIONS FOR THE ECONOMY AND JOB MARKET

The rise of 3D printing technology has undoubtedly revolutionized numerous industries, and its potential implications for the economy and job market are vast. As this technology continues to advance and become more accessible, it has the power to disrupt traditional manufacturing processes and reshape the way goods are produced.

One significant implication is the potential for job displacement. With 3D printing’s ability to automate certain manufacturing tasks, there is a possibility that some traditional manufacturing jobs may become obsolete. However, it is important to note that 3D printing also creates new opportunities for skilled workers. The demand for individuals who possess expertise in designing, operating, and maintaining 3D printers is expected to increase significantly.

Moreover, 3D printing has the potential to bring manufacturing closer to the consumers. With the ability to print products on-demand and closer to the point of consumption, this technology can reduce the need for large-scale production and global supply chains. This shift may lead to localized manufacturing hubs and the creation of new businesses that offer customized and personalized products.

The economy as a whole can benefit from the widespread adoption of 3D printing. It has the potential to drive innovation, as companies can rapidly prototype and iterate designs at a lower cost. This could lead to a faster pace of product development and increased competitiveness in the market.

Additionally, 3D printing technology can enable the production of complex and intricate designs that were previously challenging or impossible to create. This opens up new possibilities in various industries, such as healthcare, aerospace, and architecture. From customized medical implants to lightweight and fuel-efficient aircraft components, the potential applications are vast and can lead to advancements that benefit society as a whole.

In conclusion, the impact of 3D printing technology on the economy and job market is significant. While there may be some job displacement in certain sectors, there are also new opportunities emerging. The ability to bring manufacturing closer to consumers, drive innovation, and create unique and intricate designs has the potential to reshape industries and drive economic growth. It is crucial for individuals and businesses to adapt, embrace the opportunities, and stay at the forefront of this transformative technology.

9. ETHICAL CONSIDERATIONS AND POTENTIAL RISKS ASSOCIATED WITH 3D PRINTING

As with any revolutionary technology, there are ethical considerations and potential risks associated with 3D printing that need to be explored. While 3D printing holds immense promise and has already made significant strides in various industries, it is important to examine the potential implications it may have on society as a whole.

One ethical consideration is the issue of intellectual property rights. With the ease of replicating physical objects through 3D printing, there is a risk of unauthorized duplication of copyrighted or patented designs. This poses challenges for creators and innovators who rely on their intellectual property for financial gain and recognition. Striking a balance between encouraging innovation and protecting intellectual property rights will be crucial in the future development of 3D printing.

Another ethical concern is the potential for misuse of 3D printing technology. While the majority of individuals and businesses utilize 3D printing for legitimate purposes, there is always a risk that it may be used for nefarious activities. For example, the ability to create untraceable firearms or counterfeit products raises concerns about public safety and consumer protection. Ensuring appropriate regulations and monitoring systems are in place will be essential to mitigate these risks.

Additionally, 3D printing technology raises questions about environmental sustainability. The process of creating objects through additive manufacturing often involves the use of plastics and other materials that may have a negative impact on the environment. As the adoption of 3D printing continues to grow, it will be important to address the environmental consequences and explore more sustainable alternatives, such as using biodegradable materials or recycling printed objects.

Overall, while the potential benefits of 3D printing are vast, it is essential to consider the ethical implications and potential risks associated with its widespread use. By addressing these concerns proactively and implementing appropriate regulations and safeguards, we can ensure that 3D printing technology is harnessed responsibly and for the betterment of society.

10. CONCLUSION: THE TRANSFORMATIVE POWER OF 3D PRINTING AND ITS EXCITING POSSIBILITIES

In conclusion, the transformative power of 3D printing cannot be overstated. This groundbreaking technology has already begun revolutionizing various industries and has the potential to reshape the way we manufacture and create in the future.

Versatility is the most exciting aspects of 3D printing. From producing intricate and complex designs to manufacturing customized and personalized products, this technology offers endless possibilities. Traditional manufacturing methods often come with limitations, but 3D printing breaks those barriers by allowing for unprecedented creativity and innovation.

The impact of 3D printing can already be seen across diverse sectors. In healthcare, it has enabled the production of patient-specific medical implants, prosthetics, and even organs. This not only improves patient outcomes but also reduces costs and waiting times for crucial medical interventions.

In the automotive industry, 3D printing has facilitated the rapid prototyping of car parts, leading to faster design iterations and ultimately, more efficient and lightweight vehicles. This not only enhances performance but also contributes to fuel efficiency and sustainability.

Moreover, the field of architecture and construction has embraced 3D printing to create intricate and sustainable structures with reduced material waste. This technology has the potential to revolutionize the way we build homes and infrastructure, making construction processes more efficient and environmentally friendly.

As 3D printing continues to advance and become more accessible, it holds the promise of democratizing manufacturing. Small businesses and individuals can now bring their ideas to life without the need for large-scale production facilities. This opens up opportunities for entrepreneurship and innovation on a global scale.

In conclusion, the transformative power of 3D printing is reshaping industries, unlocking new possibilities, and propelling us towards a future where creativity and customization are at the forefront. It is an exciting technology that will continue to push boundaries and pave the way for a new era of manufacturing and creation.

In conclusion, the impact of 3D printing technology on various industries cannot be understated. From manufacturing and healthcare to fashion and design, this revolutionary technology has the potential to reshape the way we create, produce, and innovate. As we delve deeper into its capabilities and continue to refine its applications, we can expect 3D printing to unlock endless possibilities for customization, efficiency, and sustainability. The future is bright for this transformative technology, and we can’t wait to see how it revolutionizes industries even further.

——————————

References:

- https://3dprintingindustry.com/

- https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis

- https://www.youtube.com/watch?v=m12bX1eEVDM

- https://www.youtube.com/watch?v=2Z5iHh2omRA

- https://www.youtube.com/watch?v=Vx0Z6LplaMU

- https://www.youtube.com/results?search_query=3d+printing+technology+in+english+

- https://en.wikipedia.org/wiki/3D_printing